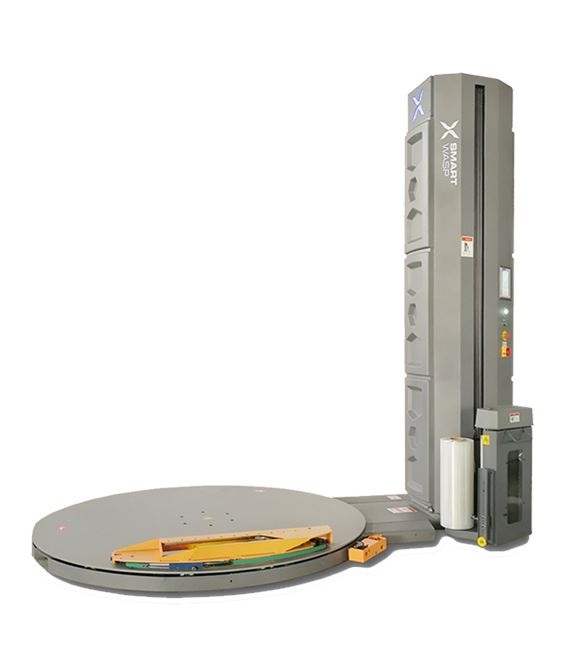

X100 Fully Automatic Pallet Wrapping Machine

Product Application

1.Pallet stretch wrapping machine use LLDPE stretch film as the main packing material to wrap the bulk cargos stacked on the pallet

2.Film provides extra support during transportation and storage to protect them from dust, moisture or damage

3.The pallet wrapping machine has been widely used in industries such as glassware, tools, electric & electronic, paper,pottery, food & beverage, etc.

Main Features

1. High efficiency and low electricity-consumption, convenient in operation.

2. The wrapping type and times can be designed on customers’ requirements.

3. Photoelectric sensor test pallet height automatic

4. Auto reset of turntable

5. Pre-stretch ratio: 300%

6. Programmable control and frequency converter is available.

7. PLC control ,manual optional. Wrap cycle (top, bottom, reinforcement) adjustment.

Variable lift speed/ film tension control. Film up/down controls.

8. Pallet stretch wraping machine soft start and soft stop.

9. Suitable for heavy pallet

10. Remote control system,fully automatic cut and clamp film

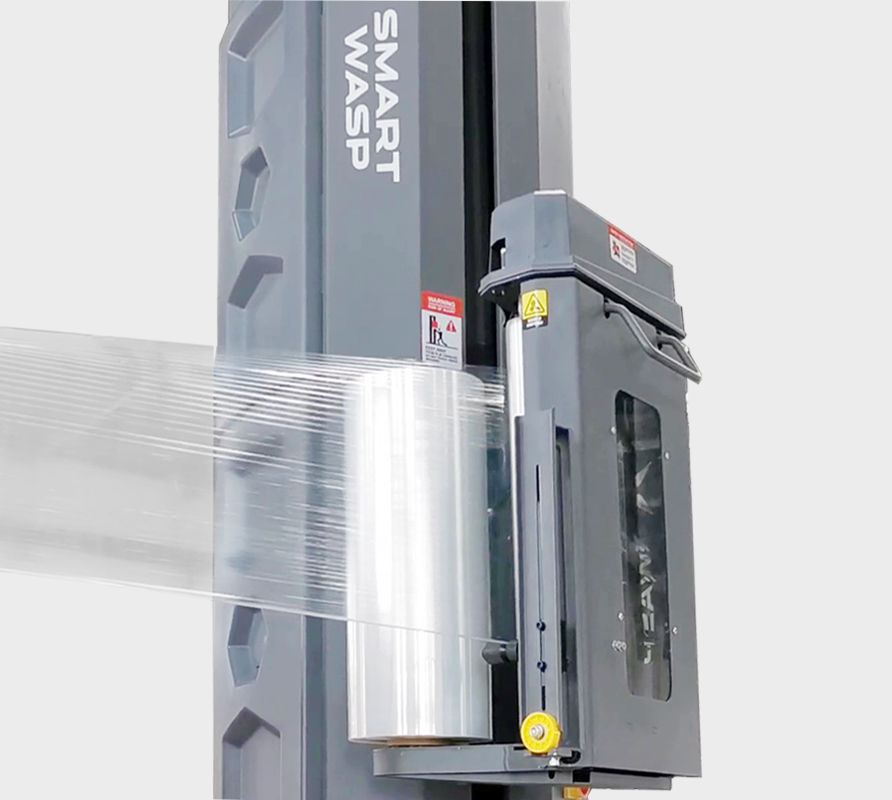

Automatic Cut and Clamp Film

X100 automatic cut and clamp film system, let workers don't need to manually cut film and put film on pallet any more, cut & clamp fim system will do it automatically

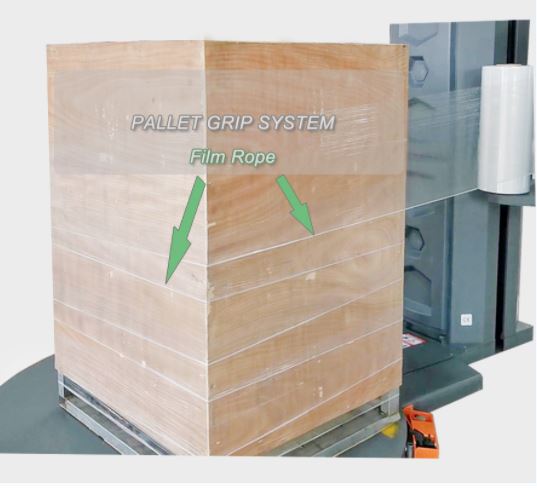

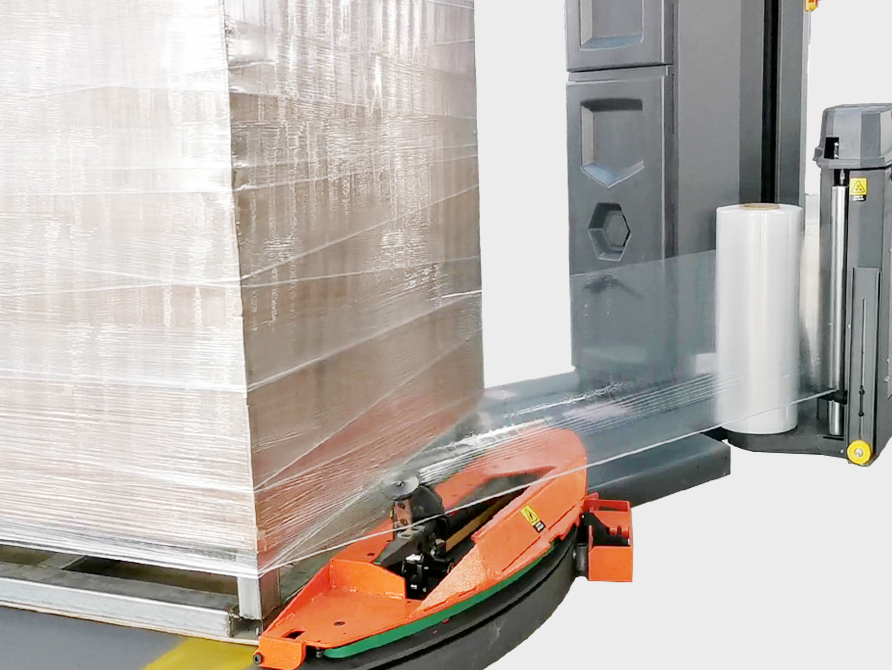

Pallet Grip System

Pallet grip system: film bottom narrowed to become film rope, film rope grip to pallet & products during wrapping.

1. During transporting, donn't need worry the products fall down when the pallets get violent vibration.

2. If the forklift damage the film on the bottom of pallet, the film will not break .

3. Pallet bottom grip and whole journey grip rope system can be instead of the horizontal strapping machine

Saving Film Consumption

Maximum up to 380% pre-stretch rate

Minimum the value of each meter of stretch film

Standard constant releasing film

Fixed-pointed wrapping quantitative use film

Multi-layer Function

This function can set different wrapping circles, wrapping force at any height that you want. Maximum one pallet can set 9 layers. Normal machines' wrapping force from bottom to top is the same in market, and they cannot stop or achieve reinforce wrapping function during wrapping

Better Spare Parts

SIEMENS PLC

SICK proximity switch

AUTONICS photoelectric switch

WEIDMULLER terminal block

SIEMENS Inverter

OMRON 24DC supply

Advanced Safety Technology

1. Safety device under film carriage to protect the foot or head of the operator

2. Transparent board makes it easy to find problem without opening door

3. Up and down belt deviation and demaged alarm system. Alarming in time to avoid carriage dropping down.

Intelligent Operation Guiding System

1. X100 with LED indicator on machine

Ready for work--Blue color

During working--Green color

Alarm--Red color

2. Touch screen guide the user how to operate machine. If alarm appears,

touch screen will show you how to solve problem

Technical Data

| Brand | SmartWasp |

| Model | X100 |

| Load weight | Maximum 2000KG |

| Turntable speed | 3-12 RPM/mins |

| Packing height | Maximum 2400mm |

| Turntable size | 1650mm(1800mm/2000mm) |

| Stretch Type | 300% (Motor) |

| Up&down speed | 1.5 ~5.5m/min. |

| Wrapping speed | 20-30 loads (Pallet: 1.0x1.2x1.8m.) |

| Film Width | 500mm(750mm optional) |

| Film diameter | 250mm |

| Film paper Core | 76 mm (50 mm optional) |

| Film weight | Maximum 17KG |

| Machine power | 1.5KW |

| Voltage | 220V-240V/50/60HZ Single-Phase |

| Machine weight | 750KG |

| Machine size | 2800*1650*2745mm(L*W*H) |

| Soft start&stop | Inclued |

| Intelligent Alarm | Inclued |

| stop at original | Inclued |

| Speed Adjustable | Inclued |

| Measure height | Automatic |

| Wrapping force | Adjustable |

| Fix film on pallet | Manual |

| PLC | SIEMENS |

| Inverter | SIEMENS |

| Touch screen | SIEMENS |

| Sensor brand | SICK (Germany Brand) |

| safety device | film carriage bottom safety |

| Certificate | CE |

| Pallet grip system | Inclued |

| Product Memory | Five Mode |

| Optional device | Ramp ,Weighing scale |

| Cut film clamp film | Fully automatic |

| Remote start machine | Have |